Maximize uptime with the right construction fleet management solutions.

Download brochureMeet today’s challenges with leading smart fleet tech.

Small job or big, you need to get it done, safely—while facing harsh conditions, constant risk and inflexible deadlines. You need a single, real-time view into every construction fleet asset and piece of heavy equipment: old and new, across manufacturers. We embrace your challenges as our own and support your mixed fleet from one job to the next.

See what you can do with a single view.

Optimize every driver, operator, construction fleet asset and jobsite. Take two minutes to see how Zonar smart fleet management solutions unify your view into performance, health, safety, inspections and asset utilization wherever you deploy an asset. Access the data without digging for it.

Work your entire construction fleet from one platform.

Work your entire construction fleet from one platform.

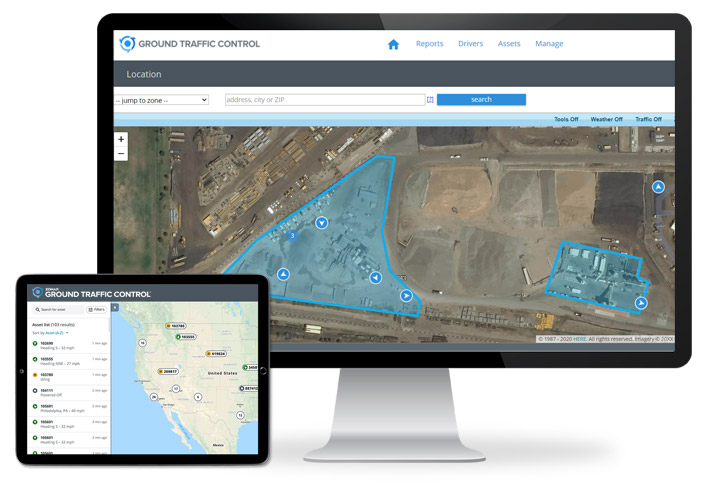

Remotely monitor and manage every mixed fleet asset—across makes, models, years and manufacturers. Enhance utilization and protect against loss with non-powered asset tracking and heavy equipment tracking. All on our web-based, mobile-friendly smart fleet management platform that opens a comprehensive view into every construction asset and jobsite.

Consolidate jobsite IoT data onto one platform to view each asset’s details through one data stream. Pinpoint locations, maximize asset utilization across sites, monitor mixed fleet asset health, and verify every required inspection.

Open visibility for greater asset utilization.

Open visibility for greater asset utilization.

Any asset that isn’t working isn’t earning. Make sure each one in your fleet is deployed where it should be and earning its maximum keep. Use SightIQ™ Optimize to consolidate site data into real-time information, regardless of location. Analyze efficiencies and dial in on what’s eating away at productivity.

Right-size your fleet, and reduce dependency on temporary assets and rentals. See where each construction asset is, how it’s performing and identify what’s underperforming. Plus, reduce direct labor costs through more uptime, less idling. SightIQ Optimize delivers the data, so you can focus on putting it to work.

Work assets longer with construction fleet diagnostics.

Drive more uptime and extend your ROI on each asset. Zonar SightIQ™ Predict pulls key construction fleet diagnostics data directly from each asset and piece of heavy equipment, across makes, models and manufacturers.

Track your tried-and-true workhorses’ health alongside newer construction equipment, and identify impending breakdowns before they occur. Plan more efficient preventative maintenance, even in the field. Save thousands in premature parts replacements.

Keep tabs with anywhere asset tracking.

Build a rock-solid culture of safety.

Work with our dedicated, in-house team of safety and compliance experts, each of whom lives, breathes and helps shape the regulations that govern the construction industry. Reduce jobsite violations, modernize your safety strategies, and evaluate policies to align your business’s intent and practices.

Keep tabs with anywhere asset tracking.

Protect fleet assets from loss and theft. Use a discreet asset tracking device that’s about the size of a golf ball and designed for harsh conditions. Perfect for toolboxes, mobile generators, heavy equipment, trailers, dumpsters, water tanks, portable cranes, portable scaffolds…the list goes on because so do the possibilities.

Track assets deployed in remote areas over long periods of time for up to 10 years (1 or 2 pings daily) with a field replaceable battery.

Meet today’s challenges with modern solutions.